Industrial Dust Collection & Mist Collection | AGET Manufacturing

Industrial

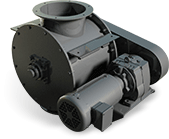

Dust Collectors & Mist Collectors

Proudly Made in Michigan Since

1938

AGET Knows Dust & Mist Collection.

AGET Manufacturing has designed and manufactured dust collectors and mist collectors since 1938.

Our exclusive collection systems, Dustkop & Mistkop, are efficient and highly-effective air filtration systems for small and large industries.

AGET Is Flexible.

We create systems that work for you and solve your problems by designing them around your facility, environment, application, and needs.

The end result is a dust or mist collection system that's perfectly tailored for you.